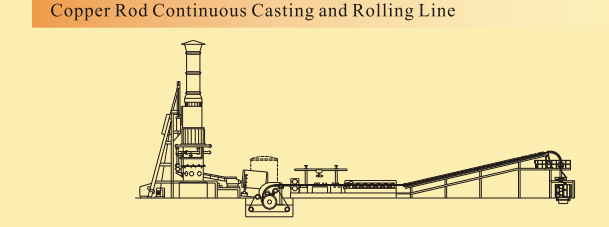

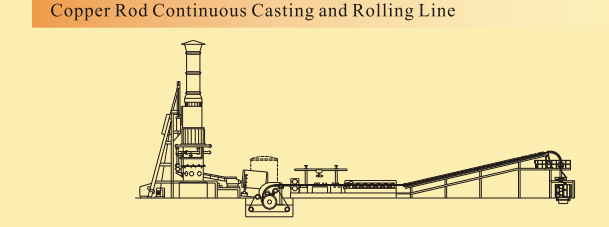

Product Description

1.Machine Name & Type

UL+Z-1800+255/12 Copper Rod Continuous Casting and Rolling Line

Copper Scrap Continuous Casting and Rolling Line

2.Machine Application

According to the different kinds of production material (copper cathode or copper scrap), we can equip

with different kinds of copper treatment furnace to produce ETP rod and FRHC rod of 8mm separately.

3.Machine Characteristic

Optimum capacity gas fired shaft furnace with automatic oxygen control system.

The continuous casting machine has been awarded the patent right.

Crystallizing wheel is in type of "H", on every side of which there is an adjustable nozzle spraying

water to ensure the crystal of the cast bar close and equal.It is easy for outer cooling and side

cooling ring to rotate out from the crystallizing wheel to adjust and maintain the cooling water.

Stainless steel is adopted as material for nozzles, inner or outer or side cooling rings, each of which

is equipped with pressure indicator and flowrate adjusting valve. The pneumatic system is used for

tightening steel belt, easy for adjusting. To clear off the moisture on the surface of the steel belt,

we adopt the flame sprayer(, the carbon coating device) and the wiper relatively.

The continuous rolling machine has a function of automatic feeding and rods stacking stop.

With an unique rolling method combining 2-high rolling stand with 3-high rolling stand, the copper

rod is provided with a good mechanic performance. The rolling emulsion and oil pipe form a closed

system with the cooler, filter and indicator for pressure of the main pipe.

The production line is provided with the function of continuous reverting for rod surface and fast cooling.

The cooling water makes a closed system by itself with cooler, filter and indicator for main pipe presssure.

To clean off the moisture on the surface of the copper rod, a blower is fixed at the end of the guiding pipe.

At the same time, an pinch-roller is installed to ensure a smooth delivery of the copper rod. The arc

guiding pipe is in a trolley-guiding construction to reduce the scratch upon the wirerods surface.

The rod is coiled by means of centrifugal (laying head). On the one hand, the copper rod is preformed before

entering the collection basket; on the other hand, the end of rod drops down into the basket automatically

in case rod broken. The collecting basket is slewing slowly and centrifugally to form orbital coils

convenient for decoiling.

The transmission system is in type of DC motors (fully-digital) speed adjusting. By adopting PLC and man-machine

interface, it can control the host and the assisting parts in type of complete line interaction. Also it can

check and display the running parameter of machines as well as indicate the breakdown.

4.Technical Data

Type) shaft furnace)

Melting furnace (Melting rate) 10 t/h

Type) (hydraulic tilting-type)

Holding furnace Capacity) 8 t

Type) stationary reverberatory furnace)

(Refining furnace) Capacity) 60-80 t

Casting ring dia.) 1800 mm

Casting machine Casting bar speed) 10.1 - 15.5 m/min

Casting bar section) 2100 mm2

Water consumption) 120 m3/h

Motor for casting ring) 4 kW

Motor of pinch roller) 5.5 kW

Shearing length) ~ 700 mm

Automatic shearer (Motor) 15 kW

No. of straightening roller) 5

Straightener & edge shaver No. of shaving tools) 4

No. of brushing rollers) 4

Cast bar brushing machine Motor) 0.75 kW

Type) 2-high mould in roughing mill)

Rolling mill 3-high mould in finishing mill)

Outlet rod dia.) 8 mm

No. of rolling stand) 14 pcs

Rollers' dia.) 255 mm

Finished rolling speed) 6 - 8.17 m/s

Production capacity) 10 - 12 t/h

Center height) 1535 mm

Main motor) 400 kW (DC)

Emulsion consumption) 90 m3/h

Max. coolant flow-rate) 100 m3/h

Rod quenching and Coolant pump motor) 15 kW

surface treatment unit Water consumption) 90 m3/h

pulling speed) 8.9 m/s

Rod orbital coiler (pulling motor) 7.5 kW

Coil's size) 1400 mm

Laying head motor) 4 kW

Collecting basket) φ1800×1500 mm

Coils’weight) 3000-5000 kg

5.Line Composition

It is made up of the melting shaft furnace, (tilted) holding furnace, (reverberatory refining furnace), casting machine,

automatic shearer and cast bar (removal) unit, accessory oil-hydraulic shearer, cast bar straightening and edge shaving

machine, rolling mill, engine oil lubrication system, emulsion lubrication system, rod quenching and surface treatment

unit, rod orbital coiler, line electric control, etc.

Payment Terms︰

TT/LC

Standards Certificate︰

ISO14001/ISO9001

Product Image