| 1.產品名稱及型號(Machine Name & Type)

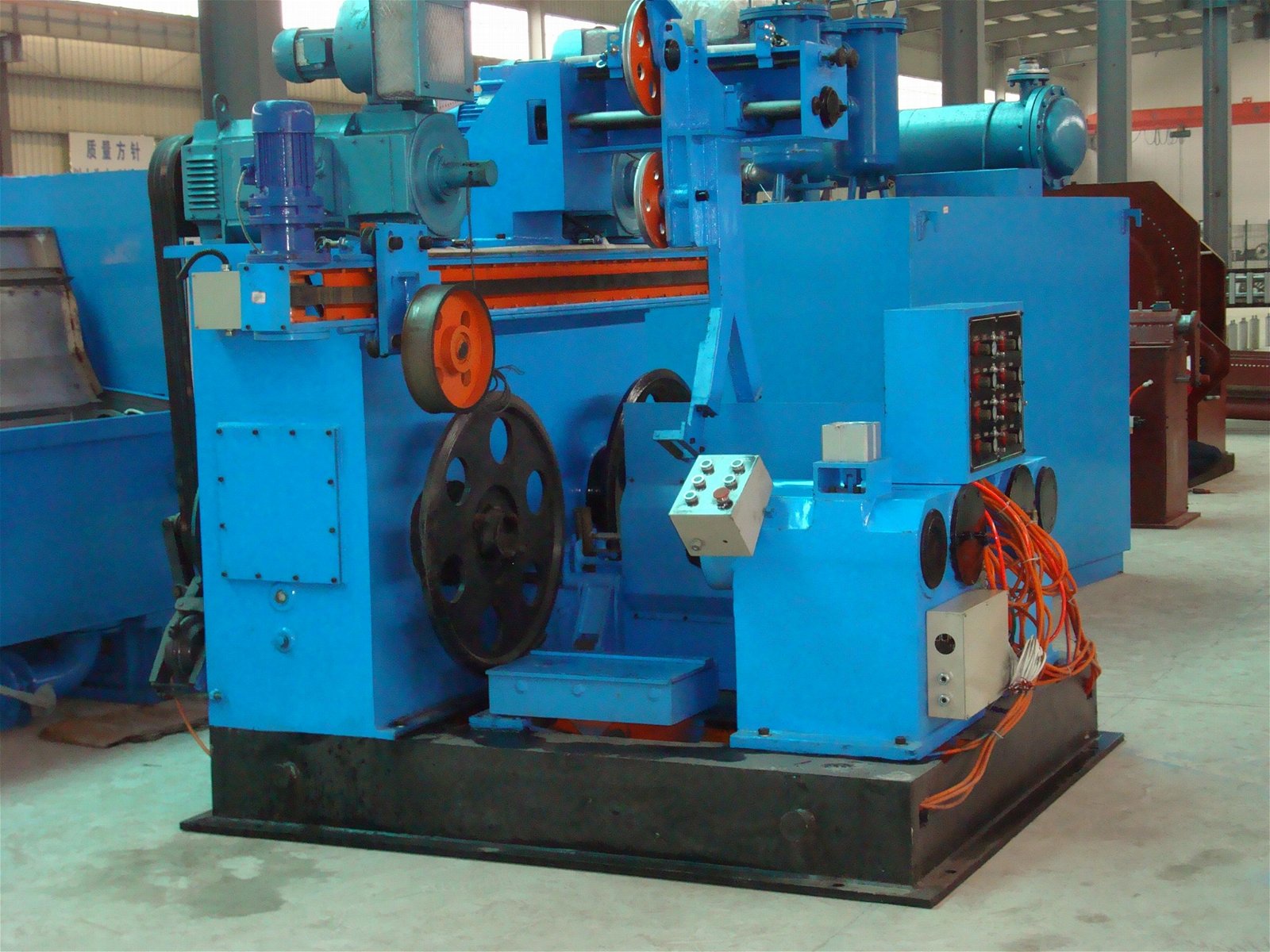

LHD-450/13(T)型直列式銅線大拉機 LHD-450/13(T) Straight-line Copper Rod Breakdown Machine 2.產品特點(Machine Characteristic) * 臥式單列9-13組拉線輪式結構,穿線操作方便 In horizontal and tandem 9-13 single step capstans, easy for threading wire. * 雙電機驅動,可實現快速換模系統 Finishing capstan separated driven for quick die-change. * 全浸沒式拉線輪可保証線材有效的冷卻和潤滑 Fully immerging capstans to ensure an effective cooling and lubricating upon wires * 退火機為臥式二段式連續交流退火,節能效果好 A horizontal resistance annealer by AC in 2 section to save power * 雙盤收線機的獨特機構保証線頭線尾壓緊,滿足絞線工藝要求 A unique mechanism of dual spooler is used for realizing the start and end of wire no-loose to meet the stranding process requirement * 本機可選配連續退火機, 自動雙盤收線機或成圈下線機 Online continuous annealer, automatic dual spooler or basket down coiler are available * 電腦控制線速度同步, 自動線模配列 MMI+PLC computer control of drawing speed synchronization and die schedule auto-arrangement 3.技術數據(Technical Data) 主 機 進線直徑(Inlet wire dia.) 8.0 mm Drawing machine 出線直徑(Outlet wire dia.) 1.3 - 4.0 mm 出線速度(Max. linear speed) 20 - 25 m/s 拉伸道次(Max. drawing pass) 13 定速輪直徑(Finish capstan dia.) 450 mm 主電機(Main motor) 280 kW (DC) 定速輪及退火電機(Finish capstan & annealer's motor) 75 kW (DC) 退火裝置 退火線徑(Annealing wire dia.) 1.3-4.0 mm Annealer 退火電壓(Max. annealing voltage) 50 V 退火電流(Max. annealing current) 5000 A 退火輪直徑(Annealing wheel dia.) 420 mm 儲線長度(Accumulating wire length) 5.0 m 雙盤收線機 收線速度(Max. take-up speed) 25 m/s Dual take-up 排線節距(MAx. traversing pitch) 6 mm/r 收線電機(Take-up motor) 22×2 kw 收線盤規格(Take-up bobbins) PND500-630 (DIN46397) 成圈收線筒尺寸(basket size): Ф800×Ф500×1650 設備總重量(Total weight) 40000 Kg 設備總尺寸(Overall dimension) 27500×4400×4500 mm 4.設備組成(Machine Composition) 機組由放線架,拉線主機,連續退火裝置,雙盤收線機或成圈下線機,電氣控制系統,軋頭穿模機,蒸汽發生器等組成。 It is composed of pay-off stand, drawing machine, online continuous annealer, dual spooler or basket down coiler, electric control system, wire pointer & stripper, vapour generator. |

| 1.產品名稱及型號(Machine Name & Type)

LHD-450/13(T)型直列式銅線大拉機 LHD-450/13(T) Straight-line Copper Rod Breakdown Machine 2.產品特點(Machine Characteristic) * 臥式單列9-13組拉線輪式結構,穿線操作方便 In horizontal and tandem 9-13 single step capstans, easy for threading wire. * 雙電機驅動,可實現快速換模系統 Finishing capstan separated driven for quick die-change. * 全浸沒式拉線輪可保証線材有效的冷卻和潤滑 Fully immerging capstans to ensure an effective cooling and lubricating upon wires * 退火機為臥式二段式連續交流退火,節能效果好 A horizontal resistance annealer by AC in 2 section to save power * 雙盤收線機的獨特機構保証線頭線尾壓緊,滿足絞線工藝要求 A unique mechanism of dual spooler is used for realizing the start and end of wire no-loose to meet the stranding process requirement * 本機可選配連續退火機, 自動雙盤收線機或成圈下線機 Online continuous annealer, automatic dual spooler or basket down coiler are available * 電腦控制線速度同步, 自動線模配列 MMI+PLC computer control of drawing speed synchronization and die schedule auto-arrangement 3.技術數據(Technical Data) 主 機 進線直徑(Inlet wire dia.) 8.0 mm Drawing machine 出線直徑(Outlet wire dia.) 1.3 - 4.0 mm 出線速度(Max. linear speed) 20 - 25 m/s 拉伸道次(Max. drawing pass) 13 定速輪直徑(Finish capstan dia.) 450 mm 主電機(Main motor) 280 kW (DC) 定速輪及退火電機(Finish capstan & annealer's motor) 75 kW (DC) 退火裝置 退火線徑(Annealing wire dia.) 1.3-4.0 mm Annealer 退火電壓(Max. annealing voltage) 50 V 退火電流(Max. annealing current) 5000 A 退火輪直徑(Annealing wheel dia.) 420 mm 儲線長度(Accumulating wire length) 5.0 m 雙盤收線機 收線速度(Max. take-up speed) 25 m/s Dual take-up 排線節距(MAx. traversing pitch) 6 mm/r 收線電機(Take-up motor) 22×2 kw 收線盤規格(Take-up bobbins) PND500-630 (DIN46397) 成圈收線筒尺寸(basket size): Ф800×Ф500×1650 設備總重量(Total weight) 40000 Kg 設備總尺寸(Overall dimension) 27500×4400×4500 mm 4.設備組成(Machine Composition) 機組由放線架,拉線主機,連續退火裝置,雙盤收線機或成圈下線機,電氣控制系統,軋頭穿模機,蒸汽發生器等組成。 It is composed of pay-off stand, drawing machine, online continuous annealer, dual spooler or basket down coiler, electric control system, wire pointer & stripper, vapour generator. |

付款方式︰ TT/LC

質量/安全認證︰ ISO14001/ISO9001